Ukuhlaziywa Kwenzuzo Ebanzi Yokushintsha Ama-Motor Asynchronous Nge-Permanent Magnet Synchronous Motors.

Siqala kusukela ezicini ze-synchronous motor unomphela uzibuthe, kuhlanganiswe nohlelo lokusebenza olusebenzayo ukuchaza izinzuzo ezibanzi zokuthuthukisa unomphela ozibuthe we-synchronous motor.

I-synchronous motor ehlobene ne-asynchronous motor, izinzuzo zesici samandla aphezulu, ukusebenza kahle okuphezulu, imingcele ye-rotor ingalinganiswa, igebe elikhulu lomoya we-stator-rotor, ukusebenza kahle kokulawula, usayizi omncane, isisindo esilula, isakhiwo esilula, isilinganiso esiphezulu se-torque / inertia, njll. i-torque), esebenza kakhulu kanye ne-Miniaturization.

Uzibuthe unomphela u-synchronous motor uqukethe i-stator ne-rotor. I-stator iyafana ne-asynchronous motor futhi iqukethe ama-windings ezigaba ezintathu kanye ne-stator core. I-stator iyafana ne-asynchronous motor, equkethe ama-windings amathathu kanye ne-stator core. I-rotor ifakwe omazibuthe bangaphambi kozibuthe (ozibuthe), ongasungula insimu kazibuthe endaweni ezungezile ngaphandle kwamandla angaphandle, kube lula ukwakheka kwemoto nokonga amandla.

Izinzuzo ezivelele ze-magnetic synchronous motor unomphela

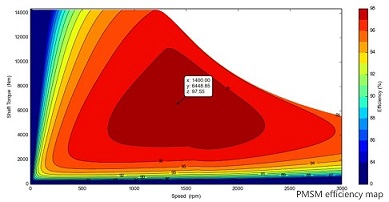

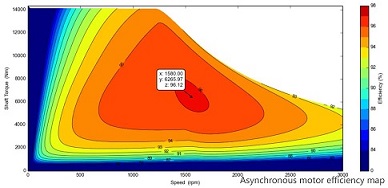

(1) Njengoba i-rotor yenziwe ngozibuthe unomphela, ukuminyana kazibuthe kuphezulu futhi asikho isidingo samanje esivusa amadlingozi, ngaleyo ndlela kuqedwe ukulahlekelwa yinjabulo. Uma kuqhathaniswa ne-asynchronous motor, inciphisa ukuvuthwa kwamanje kwe-stator side winding kanye nokulahlekelwa kwethusi nensimbi kohlangothi lwe-rotor, futhi kunciphisa kakhulu amandla amanje asebenzayo. Ngenxa yokuvumelanisa amandla e-stator kanye ne-rotor, akukho ukulahlekelwa kwensimbi okuyisisekelo ku-rotor core, ngakho-ke ukusebenza kahle (ngokuphathelene namandla asebenzayo) kanye nesici samandla (ngokuphathelene namandla asebenzayo) kuphakeme kunaleyo ye-asynchronous motor. Amamotho ayizibuthe azibuthe ahambisanayo ngokuvamile aklanyelwe ukuthi abe namandla aphezulu nokusebenza kahle ngisho nasekulayisheni ukukhanya.

(2) Amamotho asebenza unomphela ozibuthe angama-synchronous anezici zemishini eqinile kanye nokumelana okuqinile nokuphazamiseka kwetorque yemoto okubangelwa izinguquko zomthwalo. I-rotor core ye-magnetic synchronous motor unomphela ingenziwa ibe isakhiwo esingenalutho ukuze kuncishiswe inertia ye-rotor, futhi izikhathi zokuqala nezokumisa zishesha kakhulu kunama-asynchronous motors. Isilinganiso esiphezulu se-torque/inertia senza izinjini ezivumelanisiwe zikazibuthe zilungele ukusebenza ngaphansi kwezimo zokuphendula ngokushesha kunamamotho asynchronous.

(3) Ubukhulu bamamotho kamagnetic synchronous unomphela buncipha kakhulu uma kuqhathaniswa namamotho asynchronous, futhi nesisindo sawo sincishisiwe. Ukuminyana kwamandla wamamotho kazibuthe ahambisanayo anomphela anezimo ezifanayo zokulahla ukushisa nezinto zokufakwa ngaphakathi kungaphezu kokuphindwe kabili kunamamotho ezigaba ezintathu asynchronous.

(4) Isakhiwo se-rotor senziwe lula kakhulu, kulula ukusigcina, futhi sithuthukisa ukuzinza kokusebenza.

(5) Ngenxa yesici samandla aphezulu adingekayo ekwakhiweni kwama-motor asynchronous ezigaba ezintathu, kuyadingeka ukugcina igebe lomoya phakathi kwe-stator ne-rotor lincane kakhulu. Ngesikhathi esifanayo, ukufana kwegebe lomoya nakho kubalulekile ekusebenzeni okuphephile nomsindo wokudlidliza wenjini. Ngakho-ke, ama-asynchronous motors anezidingo eziqinile zomumo nokubekezelela isikhundla sezingxenye kanye nokugxila kwe-assembly, futhi kunamadigri ambalwa enkululeko yokukhetha ukuvunyelwa imvume. Ama-motor asynchronous frame amakhulu ngokuvamile asebenzisa ama-bearings agcotshwe ngamafutha okugeza, Kuyadingeka ukwengeza uwoyela wokugcoba ngaphakathi kwamahora okusebenza ashiwo. Ukuvuza kukawoyela noma ukugcwaliswa kungakabi yisikhathi ekamelweni likawoyela kungasheshisa ukwehluleka ukuthwala. Ekunakekeleni ama-motor e-asynchronous ezigaba ezintathu, ukuthwala ama-akhawunti okugcinwa kwengxenye enkulu. Ngaphezu kwalokho, ngenxa yokuba khona kwamanje okwenziwe ku-rotor ye-asynchronous motors ezigaba ezintathu, indaba yokugqwala kagesi yama-bearings nayo iye yaba nokukhathazeka kubacwaningi abaningi eminyakeni yamuva.

(6) Izinjini ezihambisanayo kazibuthe azinazo izinkinga ezinjalo. Izinkinga ezihambisanayo ezidalwe igebe elikhulu lomoya wamamothoritha azibuthe ahambisanayo anomphela kanye negebe elincane lomoya lamamotho angenhla asynchronous akubonakali kumamotho ahambisanayo. Ngasikhathi sinye, ama-bearings we-magnetic synchronous motors unomphela asebenzisa ama-grease lubricated bearings anesembozo sothuli. Ama-bearings avaliwe ngenani elifanele lamafutha okugcoba ekhwalithi ephezulu efektri, angakwazi ukugcinwa mahhala ukuphila kwakho konke.

I-Epilogue

Ngokombono wezinzuzo zezomnotho, amamotho ayizibuthe azibuthe ahambisanayo afaneleka ikakhulukazi ukuqalisa okunzima nezimo zokusebenza okulula. Ukukhuthaza ukusetshenziswa kwamamotho kazibuthe ahambisanayo anomphela kunezinzuzo ezinhle zezomnotho nezenhlalo, futhi kubaluleke kakhulu ukongiwa kwamandla kanye nokunciphisa ukungcola. Mayelana nokuthembeka nokuzinza, ama-motor synchronous kazibuthe ahlala njalo anezinzuzo ezibalulekile. Ukukhetha ama-motor synchronous kazibuthe asebenza kahle kakhulu kuwutshalomali lwesikhathi esisodwa kanye nenqubo yenzuzo yesikhathi eside.

Ngemva kweminyaka engu-16 yokunqwabelana kwezobuchwepheshe, i-Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd inekhono le-R&D lohlu olugcwele lwamamotho kazibuthe unomphela, ahlanganisa izimboni ezihlukahlukene ezifana nezimayini zensimbi, usimende, namalahle, futhi ingahlangabezana nezidingo zezimo ezihlukahlukene zokusebenza nemishini. Uma kuqhathaniswa nama-asynchronous motors of the specication, imikhiqizo yenkampani inempumelelo ephezulu, ububanzi bokusebenza komnotho okubanzi, kanye nemiphumela ebalulekile yokonga amandla. Sibheke ngabomvu ukwanda kwamabhizinisi asebenzisa izinjini zikazibuthe unomphela ngokushesha ngangokunokwenzeka ukunciphisa ukusetshenziswa nokwandisa ukukhiqizwa!

Isikhathi sokuthumela: Nov-08-2023