Umehluko phakathi kwezinhlobo ezahlukene zama-motor

1. Umehluko phakathi kwe-DC kanye ne-AC motors

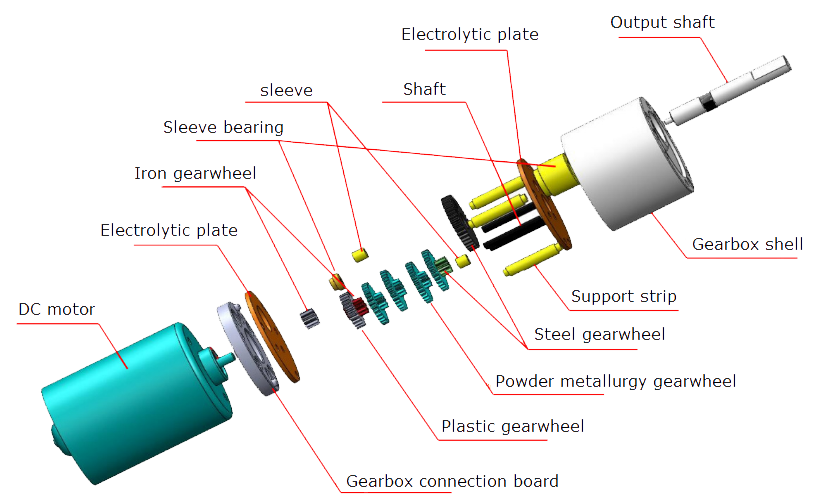

Umdwebo wesakhiwo semoto ye-DC

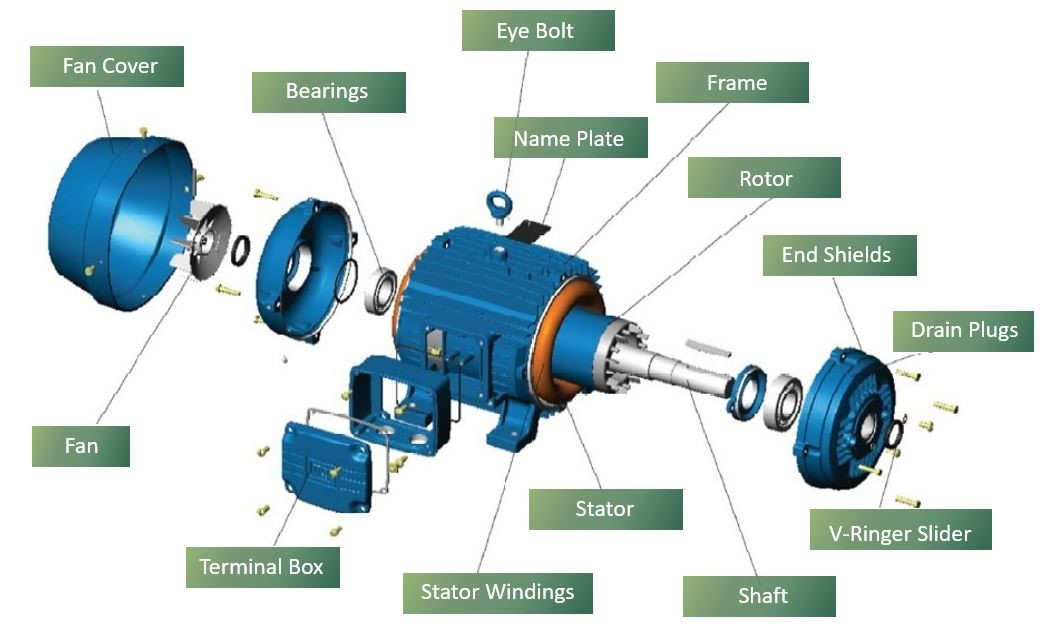

Umdwebo wesakhiwo se-AC motor

Amamotho e-DC asebenzisa i-direct current njengomthombo wawo wamandla, kuyilapho amamotho e-AC asebenzisa i-alternating current njengomthombo wawo wamandla.

Ngokwesakhiwo, umgomo wama-DC motors ulula, kodwa isakhiwo siyinkimbinkimbi futhi akulula ukusigcina. Umgomo wama-AC motors uyinkimbinkimbi kodwa isakhiwo silula, futhi kulula ukusigcina kunama-DC motors.

Ngokwentengo, ama-DC motors anamandla afanayo aphezulu kunama-AC motors. Kubandakanya idivayisi yokulawula isivinini, intengo ye-DC iphezulu kunaleyo ye-AC. Yebo, kukhona futhi umehluko omkhulu ekwakhiweni nasekugcinweni.

Mayelana nokusebenza, ngenxa yokuthi ijubane lama-motor e-DC lizinzile futhi ukulawulwa kwejubane kunembile, okungafinyeleleki ngama-AC motors, ama-DC motors kufanele asetshenziswe esikhundleni sama-AC motors ngaphansi kwezidingo eziqinile zejubane.

Ukulawulwa kwesivinini kwama-AC motors kuyinkimbinkimbi, kodwa isetshenziswa kakhulu ngoba izitshalo zamakhemikhali zisebenzisa amandla e-AC.

2. Umehluko phakathi kwama-motor synchronous kanye ne-asynchronous

Uma i-rotor ijikeleza ngesivinini esifanayo ne-stator, ibizwa ngokuthi i-synchronous motor. Uma zingafani, ibizwa ngokuthi i-asynchronous motor.

3. Umehluko phakathi kwezinjini ezijwayelekile neziguquguqukayo

Okokuqala, ama-motor ajwayelekile awakwazi ukusetshenziswa njengama-motor frequency frequency. Amamotho ajwayelekile aklanywe ngokuya ngemvamisa engaguquki kanye ne-voltage engaguquki, futhi akunakwenzeka ukuzivumelanisa ngokugcwele nezidingo zokulawulwa kwesivinini sokuguqula imvamisa, ngakho-ke awakwazi ukusetshenziswa njengama-motor ahlukahlukene.

Umthelela weziguquli zefrikhwensi kumamotho ikakhulukazi ekusebenzeni kahle nokukhuphuka kwezinga lokushisa kwamamotho.

Isiguquli semvamisa singakhiqiza amadigri ahlukene we-harmonic voltage kanye namanje ngesikhathi sokusebenza, ukuze i-motor isebenze ngaphansi kwe-voltage engeyona ye-sinusoidal kanye yamanje. Ama-harmonics aphezulu kuwo azobangela ukulahlekelwa kwe-motor stator yethusi, ukulahlekelwa kwethusi kwe-rotor, ukulahlekelwa kwensimbi nokulahlekelwa okwengeziwe kwanda.

Okubaluleke kakhulu kwalokhu ukulahlekelwa kwethusi kwe-rotor. Lokhu kulahlekelwa kuzodala ukuthi injini ikhiqize ukushisa okwengeziwe, inciphise ukusebenza kahle, inciphise amandla okukhipha, futhi ukukhuphuka kwezinga lokushisa kwamamotho ajwayelekile kuzokwenyuka ngo-10% -20%.

Imvamisa ye-frequency converter carrier isukela kuma-kilohertz ambalwa kuye kwangaphezu kwe-10 kilohertz, okwenza ukuzungeza kwe-stator kwenjini imelane nezinga eliphakeme kakhulu lokunyuka kwama-voltage, okulingana nokusebenzisa i-voltage emqansa kakhulu enjinini, okwenza ukufakwa phakathi kokuphenduka kwenjini kumelane novivinyo olunzima kakhulu.

Lapho amamotho ajwayelekile enikwa amandla iziguquli zemvamisa, ukudlidliza nomsindo obangelwa i-electromagnetic, mechanical, ventilation nezinye izici kuzoba nzima kakhulu.

Ama-harmonics aqukethwe kugesi wefrikhwensi eguquguqukayo aphazamisa i-harmonics yendawo yengxenye ye-electromagnetic yemoto, akhe amandla ahlukahlukene ashukumisayo kagesi, ngaleyo ndlela andise umsindo.

Ngenxa yobubanzi obubanzi befrikhwensi yokusebenza kwenjini kanye nebanga elikhulu lokuhlukahluka kwesivinini, amaza amaza ahlukahlukene kagesi anzima ukugwema imvamisa yokudlidliza engokwemvelo yezingxenye ezihlukahlukene zesakhiwo semoto.

Uma imvamisa yokunikezwa kwamandla iphansi, ukulahlekelwa okubangelwa i-harmonics ye-oda eliphezulu ekunikezeni amandla kukhulu; okwesibili, lapho ijubane le-motor eguquguqukayo lincishisiwe, ivolumu yomoya opholile iyancipha ngokulingana okuqondile ne-cube yejubane, okuholela ekushiseni kwe-motor kungaqedwa, ukukhuphuka kwezinga lokushisa kukhuphuka kakhulu, futhi kunzima ukufeza ukuphuma kwe-torque njalo.

4. Umehluko wesakhiwo phakathi kwamamotho ajwayelekile namamotho amafrikhwensi aguquguqukayo

01. Izidingo zezinga eliphezulu lokufakelwa

Ngokuvamile, izinga lokufakwa kwama-motor frequency frequency ngu-F noma ngaphezulu. I-insulation emhlabathini kanye namandla okufaka ama-wire turns kufanele kuqiniswe, futhi ikhono le-insulation ukumelana ne-impulse voltage kufanele licatshangelwe ikakhulukazi.

02. Izidingo zokudlidliza eziphezulu nomsindo zamamotho ashintshashintshayo

Amamotho ashintshashintshayo amafrikhwensi kufanele acabangele ngokugcwele ukuqina kwezingxenye zemoto kanye nakho konke, futhi azame ukwandisa imvamisa yawo yemvelo ukuze agweme ukuzwakala kwegagasi ngalinye lamandla.

03. Izindlela zokupholisa ezihlukene zamamotho amafrikhwensi aguquguqukayo

Amamotho ashintshashintshayo ngokuvamile asebenzisa ukupholisa umoya okuphoqelekile, okungukuthi, ifeni eyinhloko yokupholisa injini ishayelwa injini ezimele.

04. Kudingeka izindlela zokuvikela ezehlukene

Izinyathelo zokuvikela ezithwalayo kufanele zamukelwe kumamotho ashintshashintshayo anamandla angaphezu kuka-160KW. Kulula kakhulu ukukhiqiza i-asymmetry ye-magnetic circuit kanye ne-shaft current. Lapho i-current ekhiqizwa ezinye izingxenye ze-high-frequency ihlanganiswa, i-shaft current izokwanda kakhulu, okuholela ekulimaleni okuthwalayo, ngakho-ke izinyathelo zokufakelwa zivame ukuthathwa. Kumamotho ashintshashintsha amandla ashintshashintshayo, lapho isivinini sidlula u-3000/min, amafutha akhethekile amelana nezinga lokushisa eliphezulu kufanele asetshenziselwe ukunxephezela ukunyuka kwezinga lokushisa kwebheringi.

05. Isistimu yokupholisa ehlukene

Ifeni yokupholisa ye-frequency motor isebenzisa ukunikezwa kwamandla okuzimele ukuze kuqinisekiswe umthamo wokupholisa oqhubekayo.

2.Ulwazi oluyisisekelo lwamamotho

Ukukhetha imoto

Okuqukethwe okuyisisekelo okudingekayo ekukhethweni kwezimoto yilezi:

Uhlobo lomthwalo oshayelwa, amandla alinganiselwe, i-voltage elinganiselwe, isivinini esilinganiselwe, nezinye izimo.

Layisha uhlobo · DC motor·Asynchronous motor · Synchronous motor

Emishinini yokukhiqiza eqhubekayo enomthwalo ozinzile futhi azikho izidingo ezikhethekile zokuqalisa nokubhuleka, ama-motor synchronous kazibuthe unomphela noma ama-squirrel cage asynchronous motors kufanele akhethwe, asetshenziswa kabanzi emishinini, amaphampu amanzi, abalandeli, njll.

Emishinini yokukhiqiza evame ukuqala kanye nokubhuleka futhi edinga i-torque enkulu yokuqala kanye ne-braking, efana nokhreyini bebhuloho, ama-hoist asemayini, ama-air compressor, izigayo eziginqikayo ezingabuyiseleki emuva, njll., kufanele kusetshenziswe izinjini ezihambisanayo zikazibuthe ezihlala njalo noma ama-asynchronous motors.

Ezikhathini ezingenazo izidingo zokulawulwa kwesivinini, lapho isivinini esiqhubekayo sidingeka khona noma isici samandla sidinga ukuthuthukiswa, amamotho asebenza ngozibuthe ahambisanayo kufanele asetshenziswe, njengamaphampu amanzi anomthamo ophakathi nendawo nomkhulu, ama-compressor emoyeni, ama-hoists, izigayo, njll.

Emishinini yokukhiqiza edinga uhla lokulawula isivinini elingaphezu kwe-1:3 futhi idinga ukulawulwa kwejubane okuqhubekayo, okuzinzile futhi okubushelelezi, kuyalulekwa ukuthi usebenzise ama-motor synchronous kazibuthe unomphela noma amamotho e-DC ajabule ngokwehlukana noma ama-squirrel cage asynchronous motors anokulawulwa kwesivinini esishintshashintshayo, njengamathuluzi amakhulu omshini wokunemba, ama-gantry planers, njll.

Ngokuvamile, injini inganqunywa cishe ngokunikeza uhlobo lomthwalo oshayelwa, amandla alinganiselwe, i-voltage elinganiselwe, kanye nesivinini esilinganiselwe semoto.

Kodwa-ke, uma izidingo zomthwalo kufanele kuhlangatshezwane nazo ngokufanele, lezi zinhlaka eziyisisekelo zikude nokwanele.

Eminye imingcele okudingeka ihlinzekwe ihlanganisa: imvamisa, isistimu yokusebenza, izidingo zokugcwala ngokweqile, izinga lokufakwa kwe-insulation, izinga lokuvikela, isikhashana se-inertia, ijika le-torque elimelana nomthwalo, indlela yokufaka, izinga lokushisa elizungezile, ukuphakama, izidingo zangaphandle, njll. (kuhlinzekwe ngokuvumelana nezimo ezithile)

3.Ulwazi oluyisisekelo lwamamotho

Izinyathelo zokukhetha imoto

Lapho injini isebenza noma ihluleka, izindlela ezine zokubuka, ukulalela, ukuhogela nokuthinta zingasetshenziswa ukuvimbela nokuqeda iphutha ngesikhathi ukuze kuqinisekiswe ukusebenza okuphephile kwemoto.

1. Bheka

Qaphela ukuthi kukhona yini okungavamile ngesikhathi sokusebenza kwemoto, okubonakaliswa ngokuyinhloko kulezi zimo ezilandelayo.

1. Uma i-stator winding ifinyezwa, ungase ubone intuthu iphuma emotweni.

2. Uma i-motor igcwele kakhulu noma isebenza ekulahlekelweni kwesigaba, ijubane lizohamba kancane futhi kuzoba nomsindo "wokubhuza" osindayo.

3. Lapho injini isebenza ngokujwayelekile, kodwa ima kungazelelwe, uzobona izinhlansi ziphuma ekuxhumekeni okuxekethile; i-fuse ishaywa noma ingxenye ibambekile.

4. Uma i-motor idlidliza ngobudlova, kungenzeka ukuthi idivayisi yokudlulisela ibambekile noma i-motor ayilungiswanga kahle, ama-bolts onyawo akhululekile, njll.

5. Uma kukhona ukuguquguquka kombala, izimpawu zokushiswa nezimpawu zentuthu ezindaweni zokuthintana nezixhumo ngaphakathi kwenjini, kusho ukuthi kungase kube khona ukushisa okweqile kwendawo, ukuthintana okungekuhle ekuxhumekeni kwekhondatha noma ukushiswa kwamawindi, njll.

2. Lalela

Uma i-motor isebenza ngokujwayelekile, kufanele ikhiphe umfaniswano kanye nomsindo "wokuduma" okulula, ngaphandle komsindo nemisindo ekhethekile.

Uma umsindo uphezulu kakhulu, okuhlanganisa umsindo kazibuthe, umsindo ophethe, umsindo wokungenisa umoya, umsindo wokungqubuzana komshini, njll., kungase kube isandulela noma iphutha.

1. Ngomsindo we-electromagnetic, uma injini yenza umsindo ophezulu, ophansi futhi osindayo, izizathu zingase zibe kanje:

(1) Igebe lomoya phakathi kwe-stator ne-rotor alilingani. Ngalesi sikhathi, umsindo uphakeme futhi uphansi, futhi isikhawu phakathi kwemisindo ephezulu nephansi ihlala ingashintshile. Lokhu kubangelwa ukugqoka okuthwala, okwenza i-stator ne-rotor ingagxili.

(2) Umsinga wezigaba ezintathu awulingani. Lokhu kubangelwa ukuthi ukujika kwezigaba ezintathu kusekelwe phansi ngendlela engafanele, i-short-circuited noma ukuxhumana okungalungile. Uma umsindo uphansi kakhulu, kusho ukuthi injini igcwele kakhulu noma isebenza ngendlela elahlekile.

(3) Umgogodla wensimbi uxega. Ngesikhathi sokusebenza kwenjini, ukudlidliza kubangela ukuthi amabhawodi okulungisa umgogodla wensimbi axege, okubangela ukuba ishidi lensimbi eliwumgogodla we-silicon lixege futhi lenze umsindo.

2. Ukuze uthole umsindo, kufanele uwuqaphe njalo ngesikhathi sokusebenza kwenjini. Indlela yokuqapha ithi: beka umkhawulo owodwa we-screwdriver ngokumelene nengxenye yokufaka i-bearing and the other end eduze nendlebe yakho, futhi ungezwa umsindo we-bearing egijima. Uma i-bearing isebenza ngokujwayelekile, umsindo uwumsindo “oheshazayo” oqhubekayo futhi omuhle, ngaphandle kokuguquguquka noma imisindo yensimbi.

Uma kwenzeka le misindo elandelayo, kuyisimo esingavamile:

(1) Kuzwakala umsindo othi “inswininiza” lapho ukuthwala kugijima. Lona umsindo we-metal friction, ngokuvamile obangelwa ukuntuleka kwamafutha ku-bearing. I-bearing kufanele ihlakazwe futhi kwengezwe inani elifanele lamafutha.

(2) Uma kwenzeka umsindo “okutshiyozayo,” lona umsindo owenziwa lapho ibhola liphenduka. Ngokuvamile kubangelwa ukomiswa kwamafutha noma ukungabi khona kwamafutha. Inani elifanele lamafutha lingengezwa.

(3) Uma kwenzeka “ukuchofoza” noma “ukukhala umsindo,” umsindo okhiqizwa ukunyakaza okungavamile kwebhola ekugibeni. Lokhu kubangelwa ukulimala kwebhola ekuthwaleni noma ukungasebenzisi isikhathi eside kwenjini, okuholela ekomisweni kwamafutha.

3. Uma umshini wokudlulisa kanye nomshini oshayelwayo wenza umsindo oqhubekayo esikhundleni somsindo oguquguqukayo, ungasingathwa ngokwalezi zimo ezilandelayo.

(1) Umsindo othi “pop” ngezikhathi ezithile ubangelwa ibhande elingalingani.

(2) Umsindo we-“dong dong” wezikhathi ezithile ubangelwa ukuxega phakathi kwe-coupling noma i-pulley ne-shaft, kanye nokuguga kokhiye noma ukhiye.

(3) Umsindo wokungqubuzana ongalingani ubangelwa ama-blade ashayisana nekhava yesiphephetha-moya.

3. Iphunga

Ukwehluleka kungabuye kugwetshwe futhi kuvinjwe ngokuhogela injini.

Vula ibhokisi lokuhlangana ulihogele ukuze ubone ukuthi alikho yini iphunga elishile. Uma kutholakala iphunga elikhethekile lopende, kusho ukuthi izinga lokushisa langaphakathi lemoto liphezulu kakhulu; uma kutholakala iphunga eliqinile lokushiswa noma iphunga elishile, kungenzeka ukuthi inethi yokulungisa ungqimba lwe-insulation yephukile noma i-winding ishisiwe.

Uma kungabikho iphunga, kuyadingeka ukusebenzisa i-megohmmeter ukukala ukumelana nokufakwa phakathi kwe-winding kanye ne-casing. Uma ingaphansi kuka-0.5 megohms, kufanele yomiswe. Uma ukumelana kungu-zero, kusho ukuthi konakele.

4. Thinta

Ukuthinta izinga lokushisa kwezinye izingxenye zemoto nakho kunganquma imbangela yephutha.

Ukuqinisekisa ukuphepha, sebenzisa ingemuva lesandla sakho ukuthinta i-motor casing kanye nezingxenye ezizungezile zokuthwala.

Uma izinga lokushisa lingajwayelekile, izizathu zingaba kanje:

1. Ukungena komoya okungalungile. Okufana nokuwa kwefeni, ukuvaleka kwemigudu yokungenisa umoya, njll.

2. Ukugcwala. I-current inkulu kakhulu futhi i-stator winding ishisa ngokweqile.

3. I-stator winding turning i-short-circuited noma i-current yezigaba ezintathu ayilingani.

4. Ukuqala noma ukubhuleka njalo.

5. Uma izinga lokushisa elizungeze i-bearing liphezulu kakhulu, kungase kubangelwe ukuthwala umonakalo noma ukungabi khona kwamafutha.

Imithetho yokushisa ephethe izimoto, izimbangela kanye nokwelashwa kokungajwayelekile

Imithethonqubo ibeka ukuthi izinga lokushisa eliphezulu lama-bearings aginqikayo akumele lidlule ku-95℃, futhi izinga lokushisa eliphezulu lama-sliding bearings akumele lidlule ku-80℃. Futhi ukukhuphuka kwezinga lokushisa akufanele kudlule ku-55℃ (ukukhuphuka kwezinga lokushisa yizinga lokushisa elithwalayo lisusa izinga lokushisa elizungezile ngesikhathi sokuhlolwa).

Izimbangela kanye nokwelashwa kokukhuphuka kwezinga lokushisa elithwala ngokweqile:

(1) Isizathu: I-shaft igobile futhi umugqa ophakathi nendawo awunembile. Ukwelashwa: Thola isikhungo futhi.

(2) Imbangela: Izikulufu zesisekelo zikhululekile. Ukwelashwa: Qinisa izikulufu zesisekelo.

(3) Imbangela: Isithambiso asihlanzekile. Ukwelashwa: Faka esikhundleni okokugcoba.

(4) Imbangela: Isithambisi sesisetshenziswe isikhathi eside kakhulu futhi asikashintshwa. Ukwelashwa: Hlanza ama-bearings bese ubuyisela okokugcoba.

(5) Imbangela: Ibhola noma i-roller ekuthwaleni konakele. Ukwelashwa: Faka esikhundleni esisha.

I-Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd.(https://www.mingtengmotor.com/) ihlangabezane neminyaka eyi-17 yokuthuthuka ngokushesha. Le nkampani ithuthukise futhi yakhiqiza izinjini zikazibuthe ezihlala unomphela ezingaphezu kuka-2,000 ezivamile, imvamisa eguquguqukayo, i-explosion-proof, i-variable frequency explosion-proof, idrayivu eqondile, kanye nochungechunge lwedrayivu eqondile yobufakazi bokuqhuma. Ama-motor asetshenziswe ngempumelelo kumafeni, amaphampu amanzi, izithuthi zamabhande, izigayo zamabhola, izixube, ama-crusher, ama-scrapers, amaphampu kawoyela, imishini yokuphotha neminye imithwalo emikhakheni ehlukene efana nezimayini, insimbi, nogesi, ukuzuza imiphumela emihle yokonga amandla kanye nokuthola udumo olubanzi.

I-copyright: Lesi sihloko siphrintiwe kabusha isixhumanisi sokuqala:

https://mp.weixin.qq.com/s/hLDTgGlnZDcGe2Jm1oX0Hg

Lesi sihloko asimeleli imibono yenkampani yethu. Uma unemibono ehlukene noma imibono, sicela usilungise!

Isikhathi sokuthumela: Nov-01-2024