1.Isingeniso

Njengesisetshenziswa esibalulekile sohlelo lwezokuthutha emayini, i-hoist yemayini inomthwalo wemfanelo wokuphakamisa nokwehlisa abasebenzi, insimbi, izinto zokwakha, njll.

Amamotho kazibuthe ahlala njalo anezinzuzo eziningi njengokuminyana kwamandla aphezulu, ukusebenza kahle okuphezulu, nomsindo ophansi. Ukuzisebenzisa kuma-hoists asemayini kulindeleke ukuthi kuthuthukise kakhulu ukusebenza kwemishini, kuyilapho kuphinde kulethe amathuba amasha nezinselele mayelana nokuqinisekisa ukuphepha.

2. Ukusetshenziswa kobuchwepheshe bezibuthe unomphela ohlelweni lwe-mine hoist drive

(1).Isimiso sokusebenza sikazibuthe esinokuvumelanisa esinokuvumelanisa

Amamotho ayizibuthe asebenza ngokulinganayo asebenza ngokususelwe emthethweni wokungeniswa kwe-electromagnetic. Isimiso esiyinhloko siwukuthi lapho i-alternating current enezigaba ezintathu idlula ekujikeni kwe-stator, kukhiqizwa inkambu kazibuthe ejikelezayo, esebenzisana nenkundla kazibuthe kazibuthe unomphela ku-rotor, ngaleyo ndlela ikhiqize itorque ka-electromagnetic ukuze ishayele injini ukuze ijikeleze. Izimo zohlelo lokusebenza lwemayini, injini idinga ukushintsha njalo phakathi kwezimo zokusebenza ezihlukene ezifana nomthwalo osindayo, isivinini esiphansi nomthwalo wokukhanya, isivinini esikhulu. I-magnetic synchronous motor unomphela ingaphendula ngokushesha ngezici zayo ezinhle kakhulu ze-torque ukuqinisekisa ukusebenza kahle kwe-hoist.

(2). Ukuthuthuka kwezobuchwepheshe uma kuqhathaniswa namasistimu okushayela endabuko

1. Ukuhlaziywa kokuqhathanisa kokuphumelela

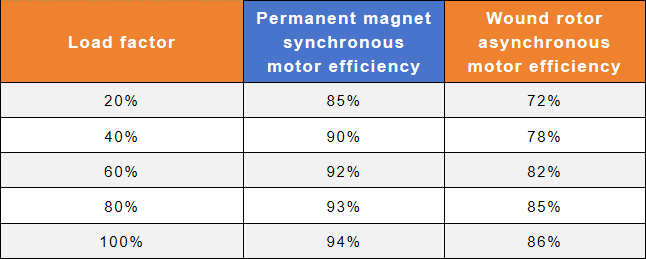

Izithuthukisi ezivamile ezimayini ngokuvamile ziqhutshwa amamotho e-asynchronous motors anenxeba, asebenza kahle kakhulu. Ukulahlekelwa kwamamotho avumelanayo ikakhulukazi kufaka phakathi ukulahlekelwa kwethusi kwe-stator, ukulahleka kwethusi, ukulahlekelwa kwensimbi, ukulahlekelwa kwemishini kanye nokulahlekelwa okungahambi kahle. Njengoba kungekho mandla ashukumisayo ku-synchronous motor unozibuthe, ukulahlekelwa kwe-rotor yayo cishe kubangelwa ithusi elincishisiwe. Ngokuqhathanisa idatha yangempela yokuhlola (njengoba kuboniswe kuMfanekiso 1), ngaphansi kwamazinga omthwalo ahlukene, ukusebenza kahle kwe-motor synchronous kazibuthe unomphela kuphakeme kakhulu kunaleyo ye-rotor-rotor asynchronous motor.Ebangeni lesilinganiso sokulayisha lika-50% - 100%, ukusebenza kahle kwe-synchronous motor yamagnetic ehlala njalo kungaba cishe ngo-100% we-synchronous motor, okungaba ngaphezulu kwe-100% ye-synchronous motor, okungaba ngaphezu kwama-2% amanxeba ukunciphisa izindleko zokusetshenziswa kwamandla okusebenza isikhathi eside kwama-hoists asemayini.

Umfanekiso 1: Ijika eliqhathanisekayo elisebenzayo le-synchronous kazibuthe motor kanye nesilonda se-rotor asynchronous motor

2. Ukuthuthukiswa kwesici samandla

Uma i-asynchronous motor ehambisana nesilonda isebenza, isici sayo samandla ngokuvamile siphakathi kuka-0.7 no-0.85, futhi izisetshenziswa ezengeziwe zesinxephezelo samandla asebenzayo ziyadingeka ukuze kuhlangatshezwane nezidingo zegridi. Isici samandla wenjini ehambisanayo kazibuthe unomphela ingaba phezulu ngokufika ku-0.96 noma ngaphezulu, eduze no-1. Lokhu kungenxa yokuthi inkambu kazibuthe ekhiqizwa isidingo sikazibuthe unomphela wokusebenza kwenjini inciphisa kakhulu amandla enjini. Isici samandla aphezulu asinciphisi kuphela umthwalo wamandla asebenzayo wegridi yamandla futhi sithuthukisa ikhwalithi yamandla egridi yamandla, kodwa futhi yehlisa izindleko zikagesi wamabhizinisi ezimayini futhi yehlise ukutshalwa kwezimali kanye nezindleko zokunakekelwa kwempahla yesinxephezelo esisebenzayo.

(3). Umthelela ekusebenzeni okuphephile kwama-hoists asemayini

1.Izimpawu zokuqalisa nokubhuleka

I-torque yokuqala yezinjini ezivumelanisiwe zikazibuthe unomphela abushelelezi futhi alawuleka ngokunembile. Ngesikhathi sokuqalwa kwe-hoist emayini, ingagwema izinkinga ezifana nokunyakaziswa kwentambo yocingo kanye nokwenyuka kokuguga kwesithungu okubangelwa umthelela wetorque oweqile lapho amamotho endabuko eqaliswa. Ukuqala kwayo kuncane futhi ngeke kubangele ukushintshashintsha okukhulu kwamandla kagesi kugridi yamandla, okuqinisekisa ukusebenza okuvamile kwezinye izinto zikagesi emayini.

Mayelana ne-braking, ama-motor synchronous azibuthe ahlala njalo angahlanganiswa nobuchwepheshe obuphambili bokulawula i-vector ukuze kuzuzwe ukulawulwa kwe-torque ye-braking enembile.Ngokwesibonelo, ngesikhathi sesiteji sokunciphisa i-hoist, ngokulawula ubukhulu kanye nesigaba se-stator current, injini ingena esimweni sokubhuleka sokukhiqiza amandla, iguqule amandla e-kinetic we-hoist ku-grid yamandla kagesi, ibuyisela amandla kagesi kanye nokuphakelayo. Uma kuqhathaniswa nezindlela zendabuko zokubhuleka, le ndlela yokubhuleka inciphisa ukuguga kwezingxenye zamabhuleki ayimishini, yandisa impilo yesevisi yesistimu yokubhuleka, inciphisa ubungozi bokuhluleka kwamabhuleki ngenxa yokushisa ngokweqile kwamabhuleki, futhi ithuthukisa ukuphepha nokuthembeka kwe-hoist braking.

2.Ukuphindaphinda amaphutha nokubekezelela amaphutha

Amanye ama-motor synchronous azibuthe ahlala unomphela asebenzisa i-multi- phase mawinding design, njenge-motor synchronous motor enezigaba eziyisithupha ezihlala unomphela ozibuthe.Lapho ukujika kwesigaba senjini kwehluleka, ama-winding esigaba esisele asengakwazi ukugcina ukusebenza okuyisisekelo kwe-motor, kodwa amandla okukhiphayo azoncishiswa ngokufanele.Leli phutha lokudizayina kabusha kwenza i-hoist yemayini ikwazi ukuphakamisa ngokuphepha i-hoisting ye-motor noma ukugwema ukwehluleka kwe-motor engxenyeni engezansi ye-motor. phakamisa ukunyakaza phakathi kwe-shaft ngenxa yokwehluleka kwemoto, ngaleyo ndlela uqinisekise ukuphepha kwabasebenzi kanye nemishini. Ukuthatha isigaba sesithupha unomphela uzibuthe motor synchronous njengesibonelo, kucatshangwa ukuthi enye yamawindi yesigaba ivulekile, ngokusho kwe-torque yokusabalalisa ithiyori ye-motor, ama-windings amahlanu asele asenganikeza cishe u-80% we-motor value ye-torque eyanele ehlobene ne-torque (ukugcina i-torque) ikheshi futhi uqinisekise ukuphepha.

3. Ukuhlaziywa kwecala langempela

(1). Amacala okufaka izicelo ezimayini zensimbi

Imayini enkulu yensimbi isebenzisa injini ye-synchronous kazibuthe ehlala unomphela ukushayela injini ehambisanayo kazibuthe enamandla alinganiselwe angu-P=3000kw. Ngemuva kokusebenzisa le moto, uma kuqhathaniswa nemoto yokuqala yesilonda esynchronous, ngaphansi komsebenzi ofanayo wokuphakamisa, ukusetshenziswa kwamandla ngonyaka kuncipha cishe ngo-18%.

Ngokuqapha nokuhlaziywa kwedatha yokusebenza kwezimoto, ukusebenza kahle kwamamotho kamagnetic synchronous motors ahlala esezingeni eliphezulu ngaphansi kwezimo ezihlukene zokusebenza, ikakhulukazi emazingeni aphakathi nendawo aphezulu, lapho inzuzo yokusebenza kahle ibonakala kakhulu.

(2). Amacala Okufaka Isicelo Semayini Yamalahle

Imayini yamalahle ifake i-hoist yemayini isebenzisa ubuchwepheshe obuhlala njalo bukazibuthe. Uzibuthe wayo unomphela we-synchronous motor unamandla angu-800kw futhi usetshenziselwa kakhulu ukuphakamisa nokuthutha abasebenzi namalahle. Ngenxa yomthamo olinganiselwe wegridi yamandla ezimayini zamalahle, isici samandla aphezulu wenjini ehambisanayo kazibuthe iwunciphisa ngempumelelo umthwalo kugridi yamandla. Ngesikhathi sokusebenza, kwakungekho ukushintshashintsha okuphawulekayo kugesi wegridi yamandla ngenxa yokuqaliswa noma ukusebenza kwe-hoist, okuqinisekisa ukusebenza okuvamile kwezinye izinto zikagesi emayini yamalahle.

I-4.Isikhathi esizayo sokuthuthuka kwemoto kazibuthe unomphela we-hoist yemayini

(1). Ucwaningo nokuthuthukiswa kanye nokusetshenziswa kwezisetshenziswa kazibuthe ezisebenza ngokugcwele

Ngokuthuthuka okuqhubekayo kwesayensi yezinto ezibonakalayo, ucwaningo nokuthuthukiswa kwezinto ezintsha ezisebenza unomphela kazibuthe sekuyisiqondiso esibalulekile ekuthuthukisweni kobuchwepheshe kazibuthe obuhlala unomphela kuma-hoists asemayini.Ngokwesibonelo, isizukulwane esisha sezinto ezingavamile zikazibuthe zomhlaba kulindeleke ukuthi sifinyelele impumelelo kumkhiqizo wamandla kazibuthe, amandla aphoqayo, ukuzinza kwezinga lokushisa, njll. ama-hoists; ukuzinza okungcono kwezinga lokushisa kuzokwenza amamotho kazibuthe unomphela akwazi ukuzivumelanisa nezimo eziqinile zezimayini, njengezimayini ezijulile zokushisa; amandla okuphoqelela anamandla azothuthukisa ikhono likazibuthe elihlala njalo lokulwa nokukhishwa kazibuthe futhi athuthukise ukwethembeka kwemoto kanye nempilo yesevisi.

(2). Ukuhlanganiswa kobuchwepheshe bokulawula okuhlakaniphile

Ngokuzayo, ubuchwepheshe bezibuthe obuhlala njalo be-hoists yezimayini buzohlanganiswa ngokujulile nobuchwepheshe bokulawula okuhlakaniphile. Ngosizo lobuhlakani bokwenziwa, idatha enkulu, i-inthanethi Yezinto nobunye ubuchwepheshe obuthuthukile, ukusebenza okukhaliphile nokugcinwa kwama-hoists kuzofezeka.Ngokwesibonelo, ngokufaka inani elikhulu lezinzwa ezingxenyeni ezibalulekile zama-motor kazibuthe ahlala unomphela kanye nama-hoists, idatha yokusebenza ingaqoqwa ngesikhathi sangempela, futhi idatha ingahlaziywa futhi icutshungulwe kusetshenziswa ukwehluleka kwe-artificial ye-algorithm, ukuhlela ukwehluleka kwemishini yokwenziwa ngaphambi kwesikhathi ukuze kufezwe ukwehluleka kokwenziwa kokugcinwa kwemishini kanye nokuxilongwa kwangaphambili. Ngasikhathi sinye, uhlelo lokulawula oluhlakaniphile lungakwazi ukwenza ngcono ngokuzenzakalelayo imingcele yokusebenza kwenjini, njengejubane, i-torque, njll., ngokuya ngezidingo zangempela zokukhiqiza yemayini kanye nesimo sokusebenza kwe-hoist, ukuze kuzuzwe inhloso yokonga amandla nokwenza ngcono ukusebenza kahle kanye nokwenza ngcono ukusebenza kahle kokukhiqizwa kanye nezinzuzo zezomnotho zemayini.

(3). Ukuhlanganiswa kwesistimu kanye nomklamo we-modular

Ukuze kuthuthukiswe ukusebenziseka kalula kanye nokugcinwa kokusetshenziswa kobuchwepheshe bukazibuthe obuhlala unomphela ezimisweni zemayini, ukuhlanganiswa kwesistimu kanye nokwakheka kwemodular kuzoba umkhuba wentuthuko. Amasistimu ahlukahlukene anjengezinjini ezisebenza ngozibuthe, amasistimu amabhuleki, kanye nezinhlelo zokuqapha ukuphepha kuhlanganiswe kakhulu ukwenza amamojula asebenzayo amisiwe. kunciphisa izindleko zokwakha ubunjiniyela. Ngaphezu kwalokho, umklamo we-modular usiza ukugcinwa nokuthuthukiswa kwemishini. Uma imojuli yehluleka, ingashintshwa ngokushesha, inciphise isikhathi sokuphumula futhi ithuthukise ukuqhubeka kokukhiqizwa kwemayini.

Izinzuzo 5.Technical of Anhui Mingteng unomphela uzibuthe motor

I-Anhui Mingteng Permanent-Magnetic Machinery & Electrical Equipment Co., Ltd.https://www.mingtengmotor.com/).yasungulwa ngo-2007. Njengamanje iMingteng inabasebenzi abangaphezu kuka-280, okuhlanganisa nabasebenzi abangaphezu kuka-50 abangochwepheshe nabachwepheshe. Isebenza ngokukhethekile ocwaningweni nasekuthuthukisweni, ekukhiqizweni nasekuthengisweni kwama-motor synchronous ultra-high-efficiency unomphela ozibuthe. Imikhiqizo yayo ihlanganisa uhla olugcwele lwe-high-voltage, i-low-voltage, imvamisa engaguquki, imvamisa eguquguqukayo, evamile, ubufakazi bokuqhuma, ukushayela okuqondile, ama-roller kagesi, imishini yonke-in-one, njll. Ngemva kweminyaka engu-17 yokuqoqwa kobuchwepheshe, inamandla okuthuthukisa uhla olugcwele lwama-motor kazibuthe unomphela. Imikhiqizo yayo ihlanganisa izimboni ezihlukahlukene njengensimbi, usimende, nezimayini, futhi ingahlangabezana nezidingo zezimo ezihlukahlukene zokusebenza nemishini.

I-Ming Teng isebenzisa ithiyori yesimanje ye-motor design, isofthiwe yomklamo ochwepheshe kanye nohlelo lokuzithuthukisa unomphela uzibuthe wemoto ukulingisa insimu kagesi, insimu yoketshezi, indawo yokushisa, indawo yokucindezeleka, njll.

6. Isiphetho

Ukusetshenziswa kwamamotho kazibuthe unomphela kuma-hoists asemayini kubonise ukusebenza okuhle kakhulu mayelana nokuphepha nokuthuthuka kwezobuchwepheshe. Kuhlelo lokushayela, ukusebenza kahle okuphezulu, isici samandla aphezulu kanye nezici ezinhle ze-torque zama-motor synchronous kazibuthe unomphela kunikeza isisekelo esiqinile sokusebenza okuphephile nokuzinzile kwe-hoist.

Ngokuhlaziywa kwecala langempela, kungabonakala ukuthi amamotho kazibuthe ahlala unomphela azuze imiphumela emangalisayo ekusetshenzisweni kwemishini yokuphakamisa imayini ezinhlotsheni ezihlukene zezimayini, noma ngabe ekwehliseni ukusetshenziswa kwamandla, ukunciphisa izindleko zokunakekela, noma ukuqinisekisa ukuphepha kwabasebenzi kanye nemishini. Uma sibheka ikusasa, ngokuthuthukiswa kwezinto zikazibuthe ezinomphela ezisebenza kahle kakhulu, ukudidiyelwa kobuchwepheshe bokulawula okukhaliphile, kanye nokuthuthukiswa kokuhlanganiswa kwesistimu kanye nokwakheka kwemodular, amamotho kazibuthe ahlala unomphela wama-hoists asemayini azoletha ithemba lentuthuko ebanzi, efaka umfutho oqinile ekukhiqizeni okuphephile nokusebenza kahle kwemboni yezimayini. Lapho ecubungula ukuthuthukiswa kobuchwepheshe be-hoist noma ukuthenga amathuluzi amasha, amakhasimende ezimayini kufanele abone ngokugcwele amandla amakhulu ezinjini ezisebenza ngozibuthe, futhi ngokunengqondo asebenzise amamotho kazibuthe ahlala unomphela ngokuhambisana nezimo zangempela zokusebenza, izidingo zokukhiqiza, namandla ezomnotho ezimayini zawo ukuze azuze intuthuko esimeme yamabhizinisi ezimayini.

I-copyright: Lesi sihloko siphrintiwe kabusha isixhumanisi sokuqala:

https://mp.weixin.qq.com/s/18QZOHOqmQI0tDnZCW_hRQ

Lesi sihloko asimeleli imibono yenkampani yethu. Uma unemibono ehlukene noma imibono, sicela usilungise!

Isikhathi sokuthumela: Dec-27-2024